TTM Machinery Precision Die And Stamping Part Sample

Video

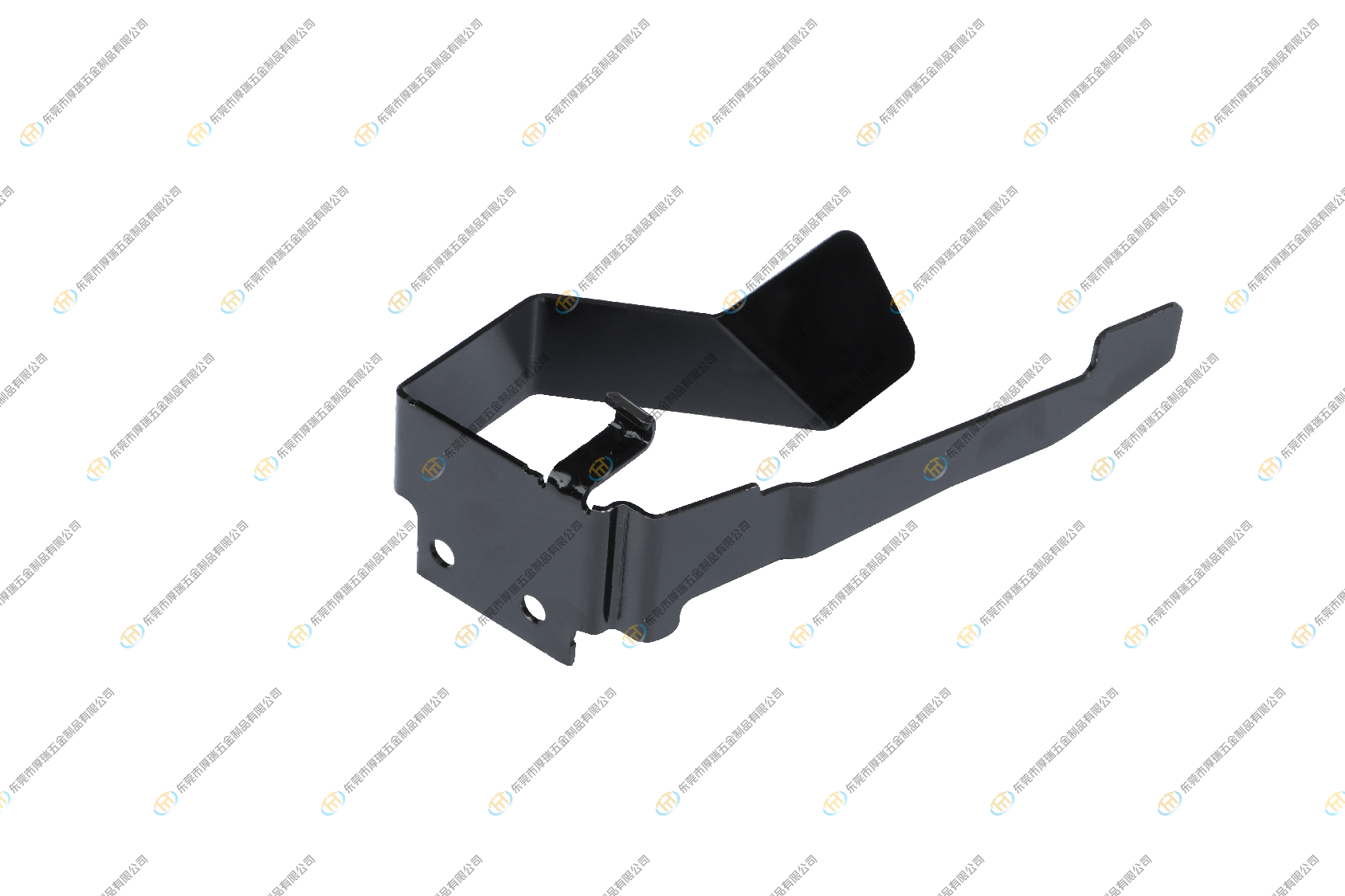

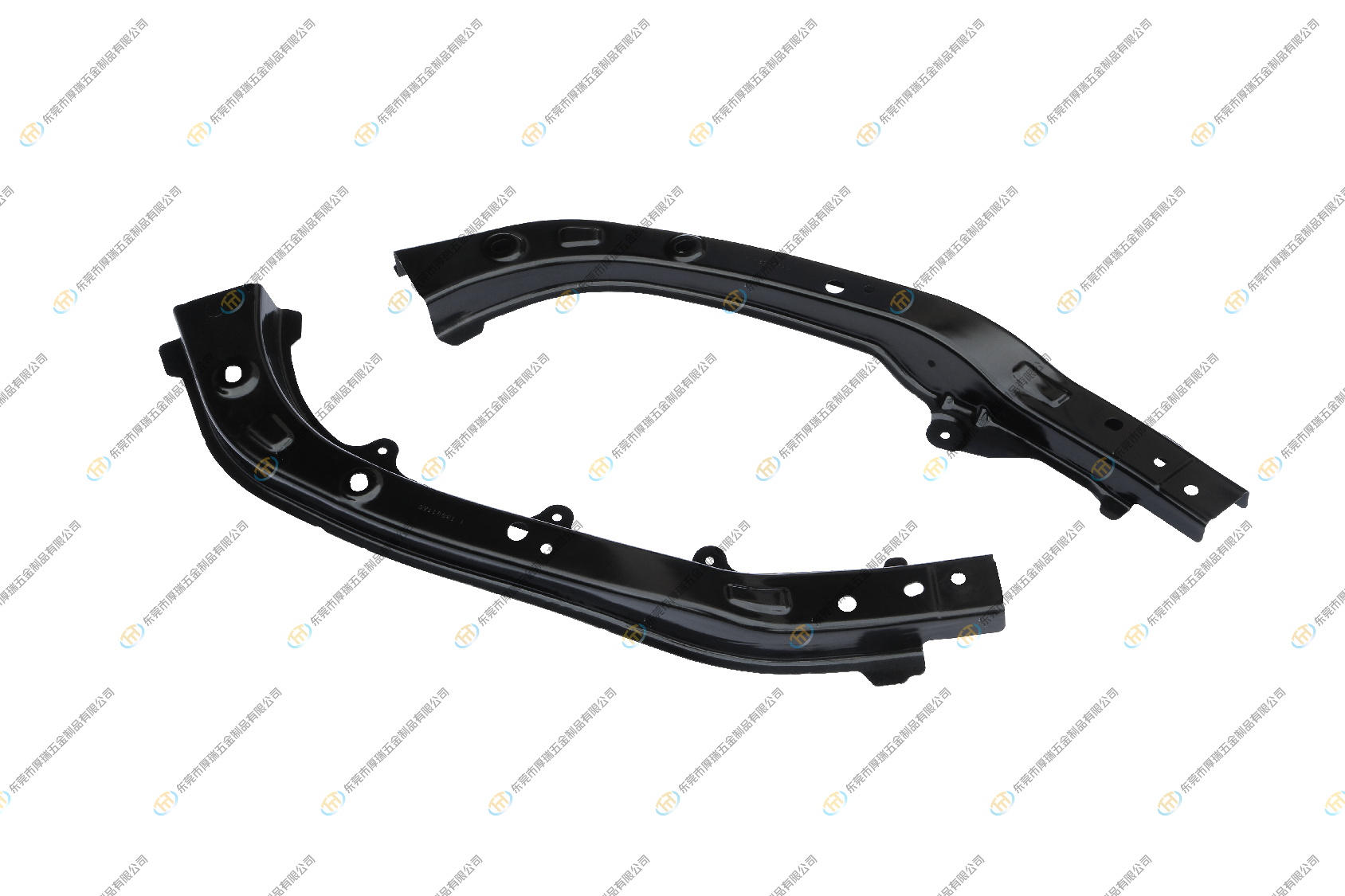

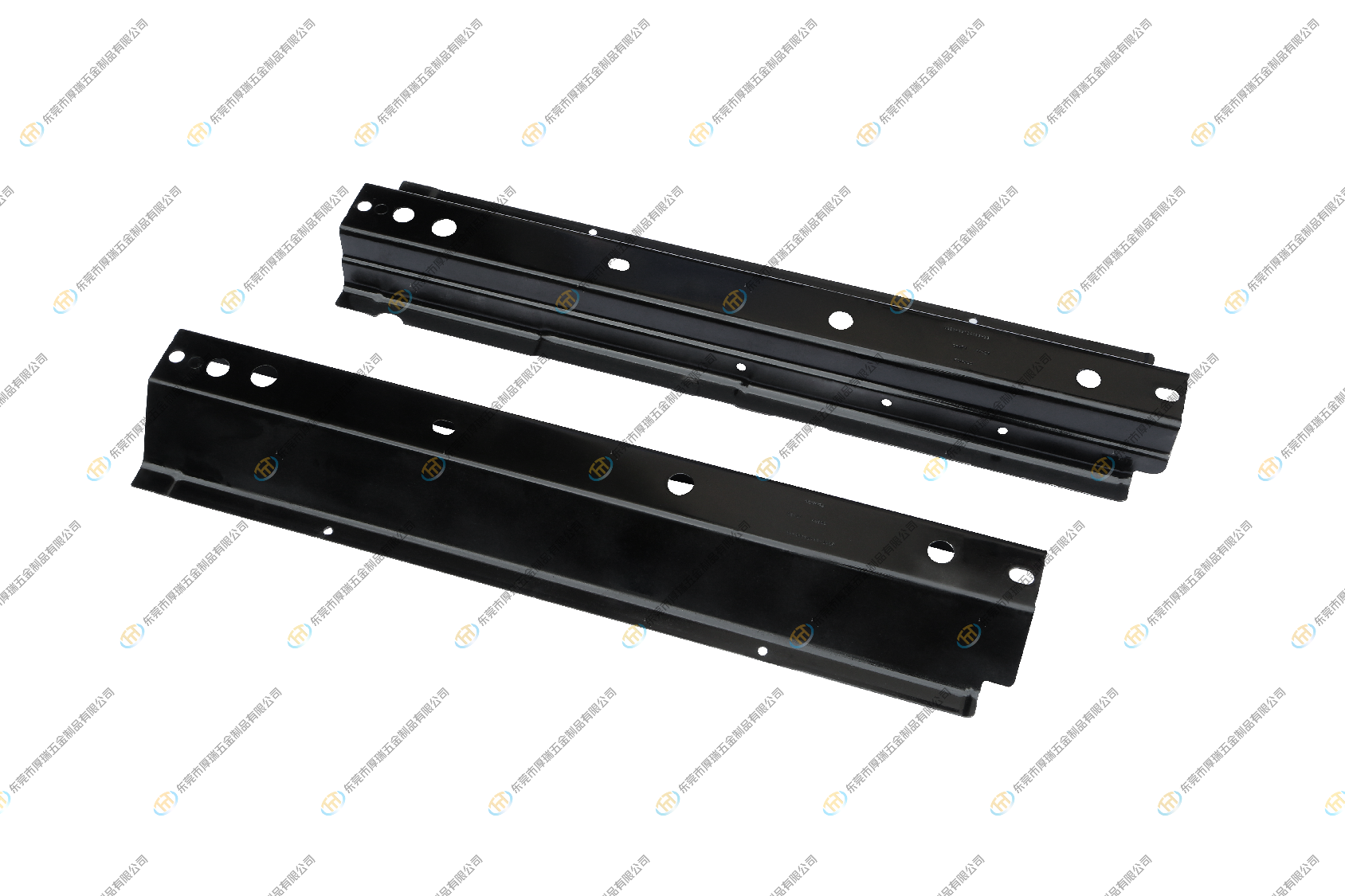

Likarolo

- Setulo morao

- Cradle ea Battery

- Cradle

- Lekanale le ka sehloohong

- etc.

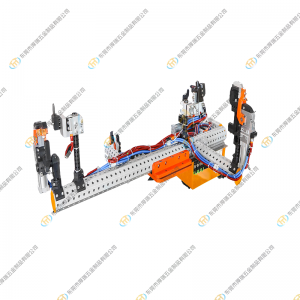

Litšoantšo tsa Tlhahiso

Selelekela

Likarolo tsa litempe li bolela likarolo tse entsoeng ka ho hatakela maqephe a tšepe ka li-dies.E na le melemo ea ho nepahala ho phahameng, boima bo bobebe, matla a phahameng, le litšenyehelo tse tlase, 'me e sebelisoa haholo likoloing, lisebelisoa tsa elektroniki, mechini le masimong a mang.Mehlala ea likarolo tsa setempe ke lisampole tse hlahisoang ka sepheo sa ho netefatsa hore na moralo o kopana le litlhoko, ho lekola boleng le ho khothaletsa mmaraka.Hangata, lisampole tsa likarolo tsa litempe tse hlahisoang ke TTM li hloka ho hlahlojoa le ho hlahlojoa ka thata ho netefatsa hore ts'ebetso ea tsona le boleng ba tsona li fihlella litekanyetso le ho fihlela litlhoko tsa bareki.

Phallo ea Rōna ea Tšebetso

1. E amohetse taelo ea ho reka-——->2. Moralo-——->3. Ho netefatsa setšoantšo / tharollo-——->4. Lokisetsa thepa-——->5. CNC-——->6. CMM-——->6. Ho bokana-——->7. CMM-> 8. Tlhahlobo-——->9. (tlhahlobo ea karolo ea 3 haeba ho hlokahala)-——->10. (ka hare/moreki setšeng)-——->11. Ho paka(lebokose la lehong)-——->12. Phano

Mamello ea Tlhahiso

1. The Flatness of Base Plate 0.05/1000

2. Botenya ba Plate ea Base ± 0.05mm

3. The Location Datum ± 0.02mm

4. Bokaholimo ± 0.1mm

5. The Checking Pins le masoba ±0.05mm

.png)

.png)