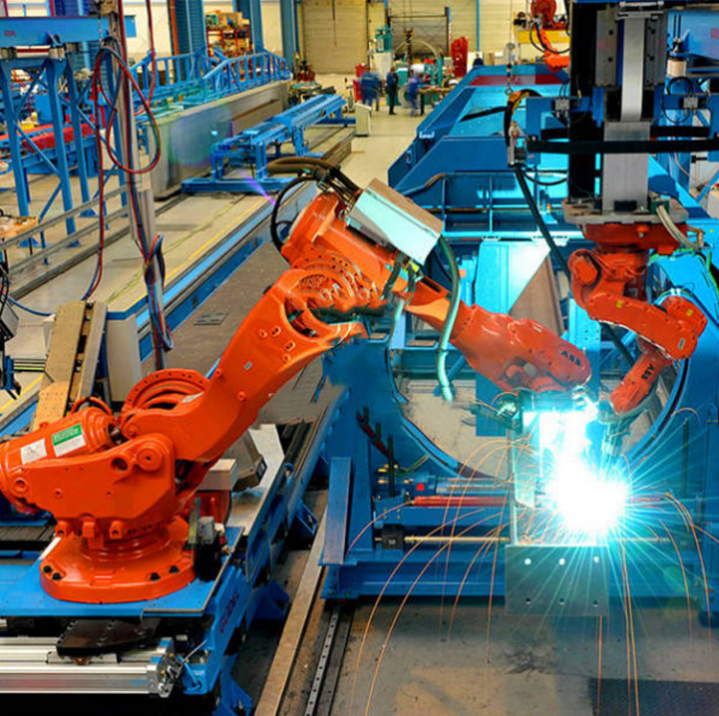

Ha indasteri ea likoloi e ntse e tsoela pele ho fetoha, ho joalo le ka theknoloji ea ho tjhesetsa likoloi.Ho tjheseletsa ka matsoho ha ho sa kgona ho fihlela ditlhoko tsa tlhahiso, mme welding e se e le karolo ya bohlokwa ya tlhahiso ya dikoloi.The automatic welding fixture ke e 'ngoe ea lisebelisoa tsa bohlokoa tsa ho etsa welding ea othomathike.

Automotive welding fixture e bua ka sesebelisoa se sebelisetsoang ho koala workpiece le boemo, ho tšehetsa le ho boloka workpiece e le boemong bo hlokahalang bakeng sa ho tjheseletsa.Sebopeho sena se lokela ho ba le litšobotsi tsa ho nepahala ho phahameng, ho tiea ho phahameng, ho tšepahala ho phahameng le bophelo bo bolelele.Ka nako e ts'oanang, lintlha tse sebetsang tse kang katleho ea tlhahiso le litšenyehelo tsa basebetsi le tsona li lokela ho nkoa.Ka hona, ho bohlokoa haholo ho rala le ho etsa li-welding tsa boleng bo holimo tsa likoloi.

Moralo le tlhahiso ea li-welding tsa automation automation li kenyelletsa mehato e latelang:

1. Tlhahlobo ea tlhokahalo: Ho latela litlhoko tsa sebele tsa tlhahiso, etsa qeto ea litekanyo tse kang mofuta, boholo, le sebōpeho sa mosebetsi oa ho tjheseletsa, hammoho le litlhoko tsa ho nepahala, botsitso le bophelo ba tšebeletso ea sesebelisoa.

2. Moralo oa sebopeho: Ho ea ka litšoaneleho tsa mochini oa mosebetsi, rala sebopeho sa sebopeho, mokhoa oa ho koala, mokhoa oa ho beha maemo, mokhoa oa ts'ehetso, joalo-joalo oa sebopeho, 'me ka nako e ts'oanang, lintlha tse joalo ka ho satalla le boima ba tlhokahalo. ho nahanoa.

3. Tlhahlobo ea mochini: Ka tlhahlobo ea lintlha le mekhoa e meng, etsa tlhahlobo ea mochini holim'a sesebelisoa, ho lekola ho satalla le ho senyeha ha sebopeho, 'me u ntlafatse sebopeho motheong ona.

4. Ho etsa le ho kopanya: Khetha lisebelisoa tse nepahetseng le mekhoa ea ho etsa le ho kopanya thepa, 'me u lokise ka mokhoa o nepahetseng hantle le ho kenya lisebelisoa tsa liteko ho netefatsa boleng le botsitso ba sebopeho.

5. Ho lokisa le ho lokisa: Ha ho etsoa tlhahiso, sebelisa lisebelisoa ka mokhoa o sebetsang, hlahloba boemo ba lisebelisoa ka nako leha e le efe 'me u etse tlhokomelo le tlhokomelo ho netefatsa hore lisebelisoa li lula li le boemong bo botle ba ho sebetsa.

Ka bokhuts'oane, moralo le tlhahiso ea li-welding tsa likoloi ke karolo ea bohlokoa ea ts'ebetso ea tlhahiso ea likoloi.Ka boqapi le boqapi ba mahlale le bo utloahalang, katleho ea tlhahiso le boleng ba lihlahisoa li ka ntlafatsoa, litšenyehelo le ts'ebeliso ea lisebelisoa tsa batho li ka fokotsoa, 'me ho ka etsoa menehelo e ntle ho nts'etsopele ea sebaka sa tlhahiso ea likoloi.

Nako ea poso: Apr-21-2023

.png)

.png)