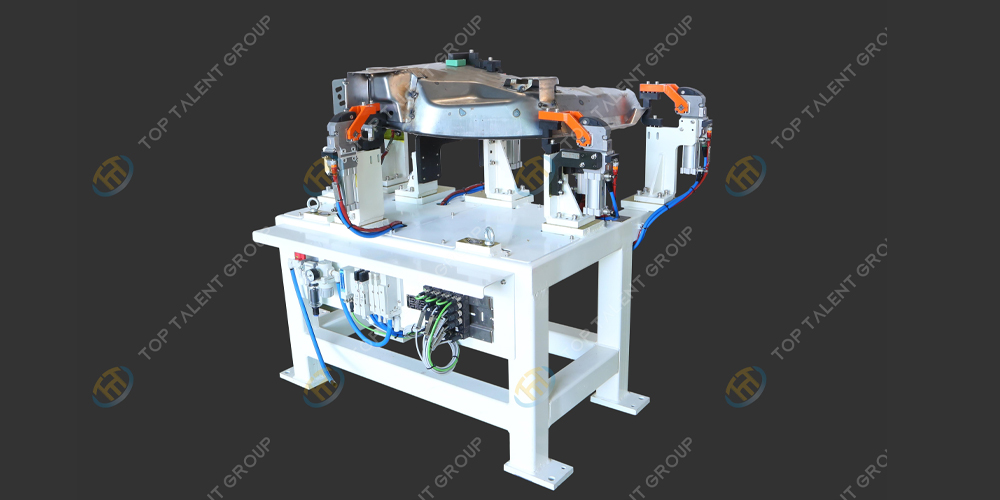

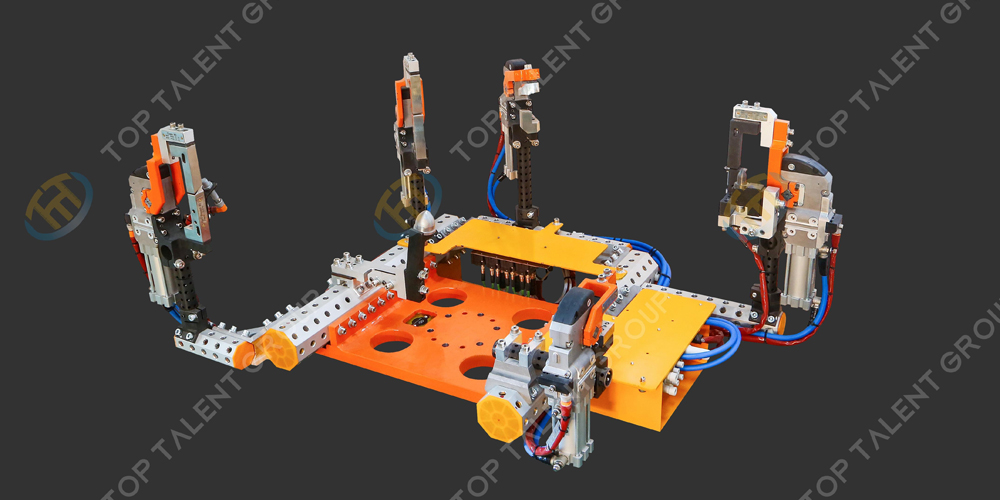

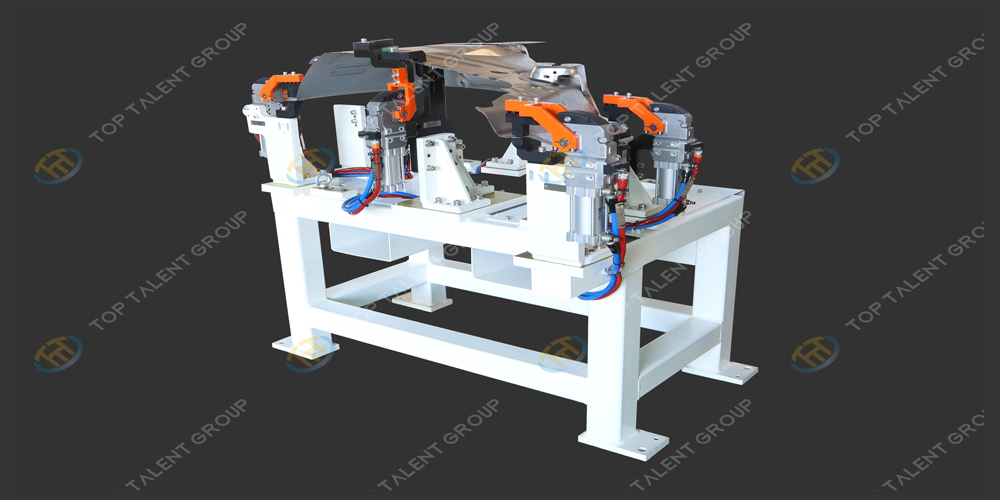

Customized Welding Lines Wheel House Arc Pneumatic Welding Fixture

Video

Lintlha tsa bohlokoa

| Mofuta oa Welding: | Arc Welding |

| Boitsebiso: | Tšepe |

| Lisebelisoa tsa Welding: | 4 Sets Gripers: 2 Sets |

| Libaka tse Rekisetsang kantle: | Canada |

| Selemo: | 2020 |

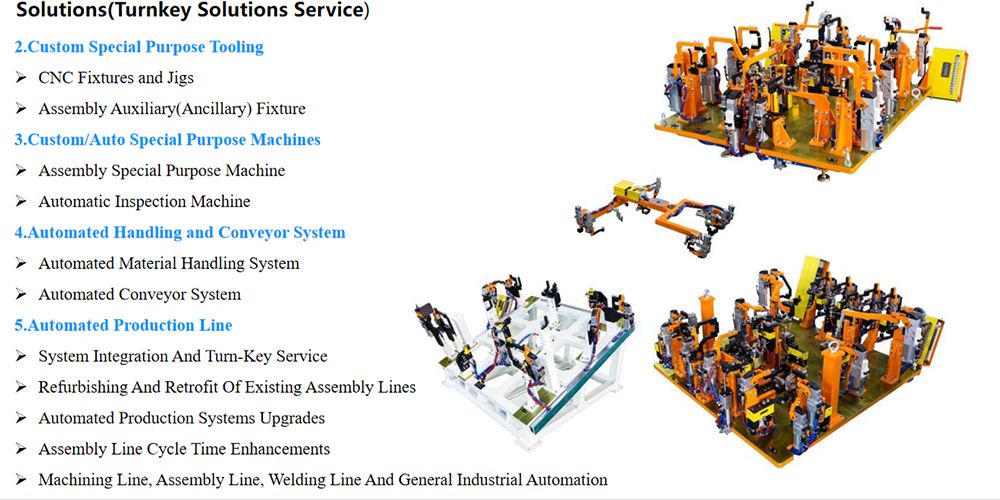

Litšoantšo tsa Tlhahiso

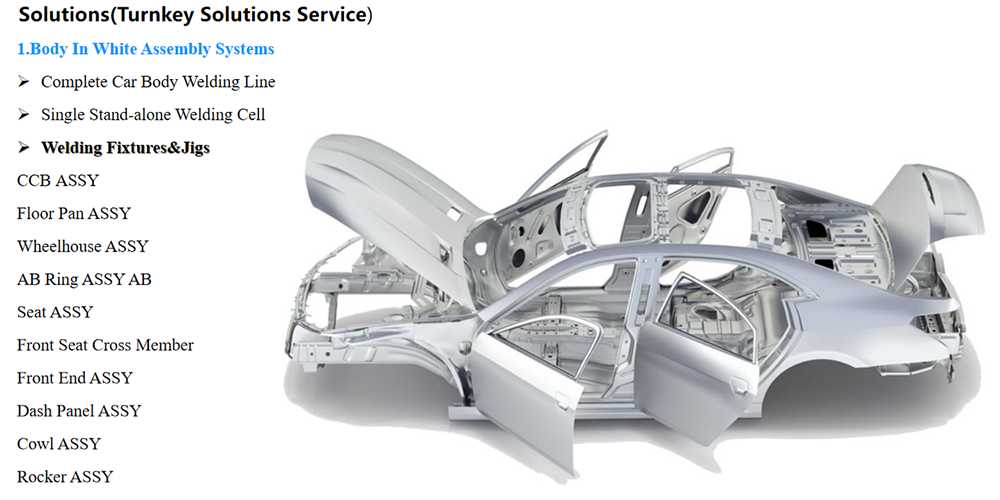

Selelekela

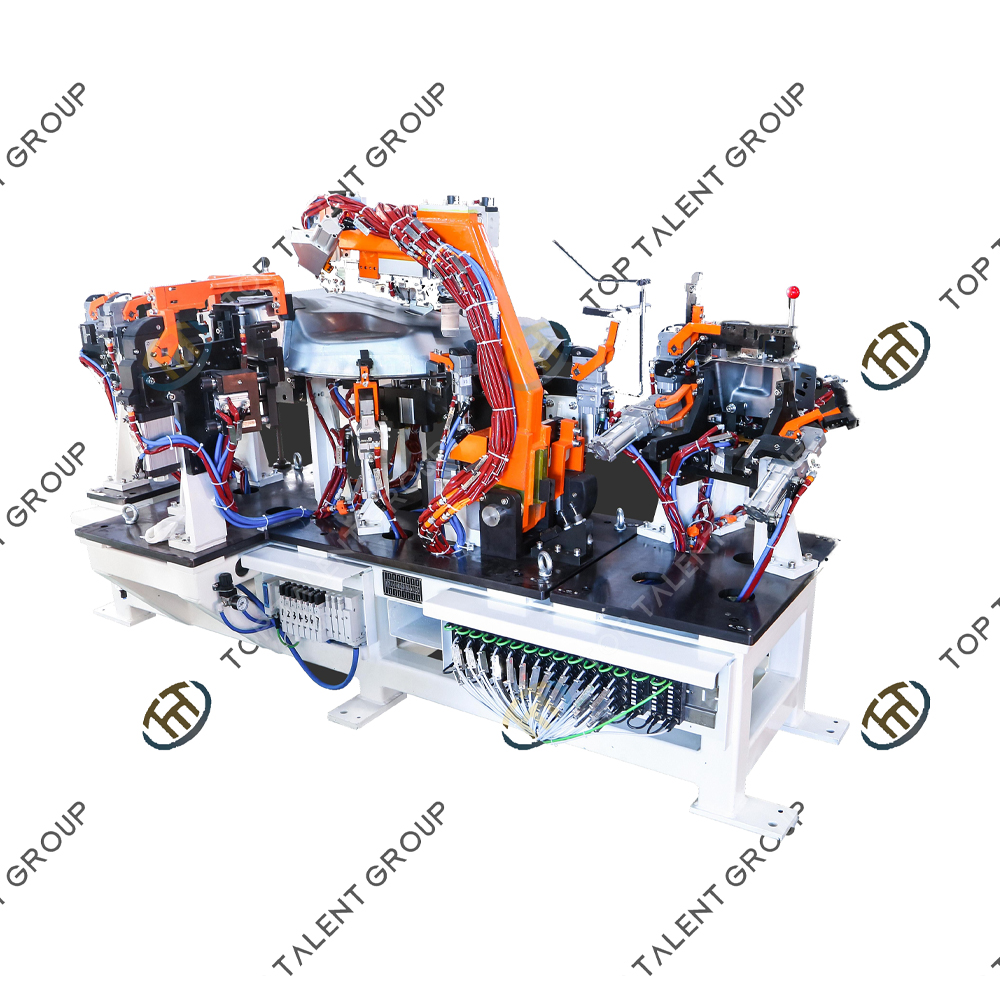

The Wheel House Welding Fixture e hlahisoang ke TTM e sebelisa mokhoa oa ho koala ka mechine ho netefatsa ho nepahala ha boemo le angle ea sekoahelo sa lebili.E ka sebelisoa 'moho le liroboto tsa welding le lisebelisoa tse ling tse ikemetseng ho fihlela ts'ebetso e sebetsang hantle le e tsitsitseng ea mabili a ntlo.Ka nako e ts'oanang, e ka boela ea netefatsa boleng ba ho tjheseletsa le ho qoba deformation le offset ea matlo a lebili nakong ea ts'ebetso ea welding, kahoo e ntlafatsa boleng le ts'ebetso ea 'mele oohle oa koloi.

Ka mantsoe a mang, Wheel House Welding Fixture ke ntho ea bohlokoa haholo indastering ea tlhahiso ea likoloi.E ka ntlafatsa ts'ebetso le boleng ba ho cheselletsa 'mele, hape ke karolo ea bohlokoahali moleng oa sejoale-joale oa tlhahiso ea likoloi.

Phallo ea Rōna ea Tšebetso

1. E amohetse taelo ea ho reka-——->2. Moralo-——->3. Ho netefatsa setšoantšo / tharollo-——->4. Lokisetsa thepa-——->5. CNC-——->6. CMM-——->6. Ho bokana-——->7. CMM-> 8. Tlhahlobo-——->9. (tlhahlobo ea karolo ea 3 haeba ho hlokahala)-——->10. (ka hare/moreki setšeng)-——->11. Ho paka(lebokose la lehong)-——->12. Phano

Mamello ea ho Etsa

1. The Flatness of Base Plate 0.05/1000

2. Botenya ba Plate ea Base ± 0.05mm

3. The Location Datum ± 0.02mm

4. Bokaholimo ± 0.1mm

5. The Checking Pins le masoba ±0.05mm

.png)

.png)