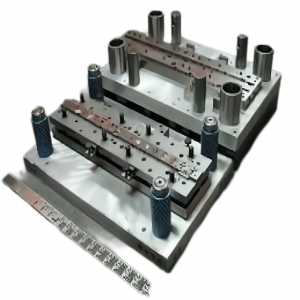

Welding Fixture For Cross Member WS Spring Link

Video

Libaka tsa Kopo

Taolo ea boleng ba indasteri ea likoloi

Bokhoni ba tlhahiso ea likoloi bo ntlafala

Tlhaloso

| Mofuta oa Tokiso: | Arc Welding |

| Boholo: | 1800x1300x900mm |

| Boima ba 'mele: | 125KG |

| Boitsebiso: | Kaho e ka Sehloohong: tšepe Tšehetso: tšepe |

| Phekolo ea sefahleho: | Base Plate: Electroplating Chromium le Black Anodized |

Lintlha tsa Sehlahisoa

Kenyelletso e Feletseng

Ena ke sehlopha sa li-welding fixture tsa WL Cross Member WS Spring Link, ka ho feletseng ka lihlopha tse 2, tseo re li etselitseng bareki ba rona ba Canada. The spring chuck shank ke sesebelisoa sa cylindrical se kentsoeng mochine oa ho sila ho koalla mochine oa ho cheka kapa oa ho roala.Kenya chuck ka har'a nate ea senotlolo 'me ka bonolo u phuthele nate ea senotlolo ka "spring chuck" holim'a shank, sehokelo kapa sehokelo.Ho ipapisitsoe le elasticity ea tšepe ea elastic ho tiisa, clamp e hlephileng e bonolo, e sebelisoang haholo bakeng sa ho koala lebone, lisebelisoa tsa ho seha moroalo o mahareng.E atisa ho sebelisoa bakeng sa lisebelisoa tsa ho itšeha tse kang li-mill, li-drill bits, lipompo, li-reamer le li-drill tse bohareng.Fetola mefuta e fapaneng ea li-clamping ka ho fetola likoleke tse fapaneng.Nakong ea ho kenya chuck le lock nut, chuck le lock nut li tlameha ho sekamelloa ho Angle e itseng ebe li kenngoa ka har'a slot ea senotlolo sa lock nut.Se ke oa sebelisa torque e atolositsoeng e matla ea wrench e thata haholo, ho thibela sesebelisoa le sebopeho se sebe sa meteorite.

Phallo ea Mosebetsi

1. E amohetse taelo ea ho reka-——->2. Moralo-——->3. Ho netefatsa setšoantšo / tharollo-——->4. Lokisetsa thepa-——->5. CNC-——->6. CMM-——->6. Ho bokana-——->7. CMM-> 8. Tlhahlobo-——->9. (tlhahlobo ea karolo ea 3 haeba ho hlokahala)-——->10. (ka hare/moreki setšeng)-——->11. Ho paka(lebokose la lehong)-——->12. Phano

Mamello ea ho Etsa

1. The Flatness of Base Plate 0.05/1000

2. Botenya ba Plate ea Base ± 0.05mm

3. The Location Datum ± 0.02mm

4. Bokaholimo ± 0.1mm

5. The Checking Pins le masoba ±0.05mm

Tshebetso

CNC Machining(Ho sila / ho Fetola), Ho sila

Electroplating Chromium le Phekolo ea Anodized e Ntšo

Lihora tsa Moqapi (h): 40h

Haha Lihora(h):150h

Taolo ea Boleng

CMM (3D Coordinate Measuring Machine), Vms-2515G 2D Projector, HR-150 A Hardness Tester

Setifikeiti sa Mokha oa Boraro se entsoeng ke Shenzhen Silver Basis Testing Technology Co., Ltd , ISO17025 Certified

.png)

.png)