TTM Robot Welding Machine Arc Welding Automated Welding Fixture

Video

Lintlha tsa bohlokoa

| Tiisetso: | 3 lilemo |

| Boitsebiso: | Ts'epe e sa beng le mabali |

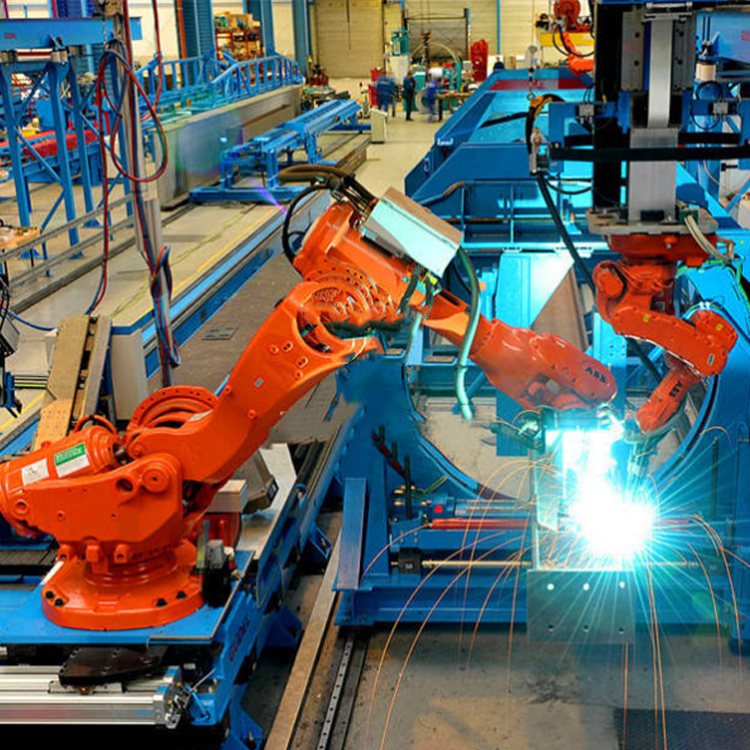

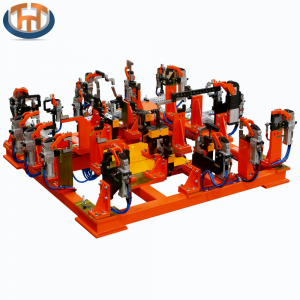

| Tšebeliso: | Ho tjhesetsa koloi |

| Mosebetsi: | Likarolo tsa Likoloi tsa Kopano ea Line |

| Ho paka: | lebokose la lehong |

Litšoantšo tsa lihlahisoa

Selelekela

Mosebetsi o ka sehloohong oa sesebelisoa sa welding ke ho netefatsa boholo ba weldment, ho ntlafatsa ho nepahala le ho sebetsa hantle ha kopano, le ho thibela deformation ea welding.Ka ho theha sebopeho se loketseng sa ho lokisa, mokhoa oa tlhahiso o ka hlophisoa ka katleho ho thusa ho leka-lekanya nako ea seteishene le ho fokotsa nako e sa hlahisoang, ka hona ho ntlafatsa katleho ea tlhahiso le tlhahiso.

TTM e ikemiselitse ho etsa lipatlisiso le nts'etsopele ea lisebelisoa tsa boleng bo holimo tsa othomathike

Phallo ea Mosebetsi

1. E amohetse taelo ea ho reka-——->2. Moralo-——->3. Ho netefatsa setšoantšo / tharollo-——->4. Lokisetsa thepa-——->5. CNC-——->6. CMM-——->6. Ho bokana-——->7. CMM-> 8. Tlhahlobo-——->9. (tlhahlobo ea karolo ea 3 haeba ho hlokahala)-——->10. (ka hare/moreki setšeng)-——->11. Ho paka(lebokose la lehong)-——->12. Phano

Mamello ea ho Etsa

1. The Flatness of Base Plate 0.05/1000

2. Botenya ba Plate ea Base ± 0.05mm

3. The Location Datum ± 0.02mm

4. Bokaholimo ± 0.1mm

5. The Checking Pins le masoba ±0.05mm

-300x3001.png)

.png)

.png)