TTM Automotive Floor Pan Automated Welding Fixtures

Video

Tlhaloso

| Mofuta oa Tokiso: | Lisebelisoa tsa Welding tsa Floor Pan |

| Bongata: | Lisebelisoa tsa Welding: 6 Sets |

| Boitsebiso: | Tšepe |

| Libaka tse Rekisetsang kantle: | Canada |

| Selemo: | 2021 |

Lintlha tsa Sehlahisoa

Kenyelletso e Feletseng

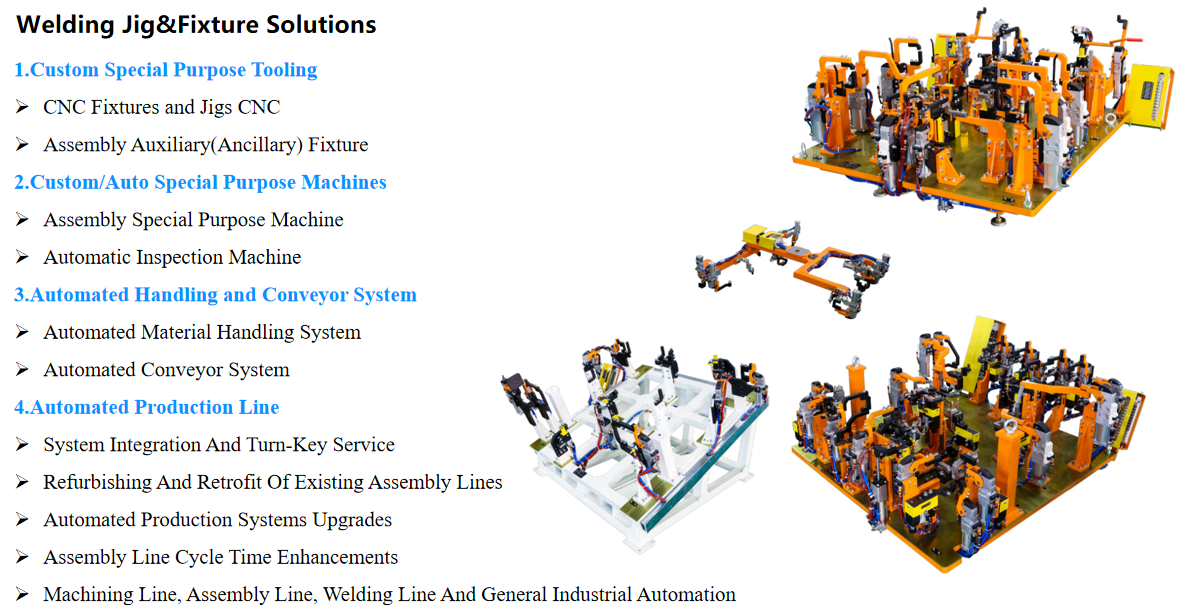

Welding fixture ke sete ea lisebelisoa tse tenyetsehang bakeng sa ho lokisa welding, compression le boemo.E sebelisoa haholo-holo bakeng sa ho tjheseletsa lisebelisoa tse fapaneng tse chesehang, lisebelisoa tse kholo, tse mahareng le tse nyane.Molebeli o ka tlase oa koloi hangata o bua ka poleiti ea enjene ea koloi.Ke sesebelisoa sa ts'ireletso ea enjene se hlophisitsoeng ho latela mefuta e fapaneng.E arotsoe ka resin ea polasetiki e thata, tšepe, alloy ea aluminium le tšepe ea polasetiki ho latela thepa ea tlhahiso.

TTM e entse lisebelisoa tsena tsa welding bakeng sa Floor Pan ka 2021.

Phallo ea Mosebetsi

1. E amohetse taelo ea ho reka-——->2. Moralo-——->3. Ho netefatsa setšoantšo / tharollo-——->4. Lokisetsa thepa-——->5. CNC-——->6. CMM-——->6. Ho bokana-——->7. CMM-> 8. Tlhahlobo-——->9. (tlhahlobo ea karolo ea 3 haeba ho hlokahala)-——->10. (ka hare/moreki setšeng)-——->11. Ho paka(lebokose la lehong)-——->12. Phano

Mamello ea ho Etsa

1. The Flatness of Base Plate 0.05/1000

2. Botenya ba Plate ea Base ± 0.05mm

3. The Location Datum ± 0.02mm

4. Bokaholimo ± 0.1mm

5. The Checking Pins le masoba ±0.05mm

.png)

.png)