TTMke k'hamphani e thehiloeng hantle e amanang le likoloi e fihletseng boemo bo phahameng ba ho iketsetsa.Re sebetsa ka ho khetheha tlhahisong ea likoloilisebelisoa tsa ho hlahloba, lisebelisoa tsa welding, lehlobo.Sehloohong sena, re ka rata ho hlahisa phello ea boleng ba matla ho tlhahiso ea likoloi.

Boemo ba theknoloji le boits'oaro ba indasteri ea ho etsa likoloi bo ntse bo phahama le ho feta, 'me ho sebelisoa palo e kholo ea tšusumetso le meroalo e se nang moeli lits'ebetsong tsa eona tsa mantlha tsa tlhahiso, joalo ka mechini ea welding ea motlakase le metjhini ea welding ea laser ka lebenkeleng la' mele, metjhini ea litempe ho. lebenkele la litempe, le lisebelisoa tsa ho fetolela khafetsa lebenkeleng la lipente., mohala oa tlhahiso ea othomathike sebokeng sa kopano, joalo-joalo, meroalo ena e na le tšobotsi e tloaelehileng, ke hore, phetoho ea mojaro e kholo haholo 'me moloko oa harmonic o moholo haholo.Ka nako e ts'oanang, ka litlhoko tse tsoelang pele tsa naha ho fokotsa tšebeliso le ho boloka matla, ho sebelisoa mabone a mangata a bolokang matla;Motors setso butle-butle nkeloa sebaka ke maqhubu a ho sokoloha kganna.Meroalo ena e mecha eo e seng ea mela e mpefatsa ho senyeha ha boleng ba motlakase indastering ea tlhahiso ea likoloi.

Mathata a hona joale a matla

Ka tlhahlobo ea lipalo-palo ea tlhahlobo ea boleng ba matla, ho fumanoa hore mathata a mantlha a boleng ba motlakase indastering ea tlhahiso ea likoloi ke li-harmonics, ho feto-fetoha ha motlakase le mathata a matla a sebetsang, ao ka kakaretso a leng teng likhokahanong tse fapaneng tse kang stamping, welding, penta, powertrain le final. kopano.

1. Setempe sa litempe - li-harmonics, ho feto-fetoha ha motlakase le ho fofa

Meroalo e boima setsing sa ho hatisa litempe e shebane haholo le mechine ea khatiso, ho kenyeletsoa liroboto le lisebelisoa tsa motlakase tsa DC.Mechine e mengata ea khatiso e tsamaisoa ke li-motor tse feto-fetohang ka lebelo la DC 'me e hloka phepelo e tsitsitseng ea DC.Li-motor tsa liroboto li laoloa ke PLC 'me li tsamaisoa ke li-converter tsa maqhubu.Li-circuits tsa taolo ea PLC le li-converter tsa frequency ka bobeli ke mojaro o tloaelehileng o bobebe.

2.Lebenkele la pente - harmonic

Sebaka sa pente sa koloi se arotsoe ka mekhahlelo e mene, primer, seaparo sa bohareng, seaparo sa motheo le varnish.Ntle le hore primer e hloka ho hokelloa letamong la betri, lits'ebetso tse ling li ts'oana.Setsi sa ho fafatsa ka boiketsetso ke sekoahelo sa tlhahiso se nang le ketane e batlang e phahame.Ho hlōleha ha thepa ea motho ka mong E tla ama ts'ebetso eohle ea lebenkele la spray.

3.Koetliso ea matla

The powertrain haholo-holo e bua ka tlhahiso ea enjene, 'me phello ea matla a motlakase e tsepamisitsoe ho lisebelisoa tsa mochine oa CNC setsing sa ho sebetsa sa machining, hammoho le lisebelisoa tsa ho tsamaisa, likhoele tsa kopano, le sethala sa liteko.Theko ea thepa e theko e boima le e rarahaneng e hloka ho seta lisebelisoa tsa mochini, ho lahla lisebelisoa, lisebelisoa tse senyang, ho emisa mela ea tlhahiso, ho emela mosebetsi, jj.

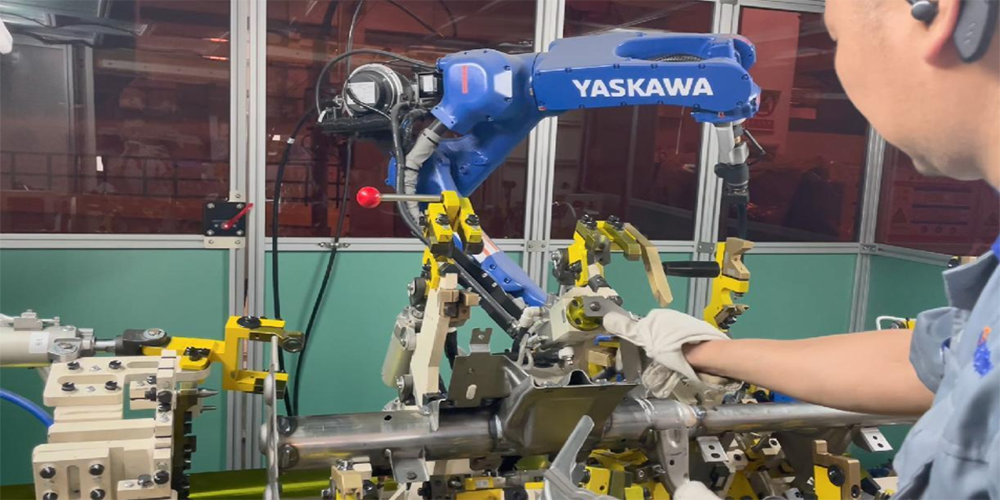

4.Kopano ea ho qetela - Harmonics

Ts'ebetso ea ho qetela ea kopano haholo-holo e sebelisa liroboto bakeng sa ho kopanya othomathike, 'me palo e kholo ea likarolo tsa elektroniki joalo ka diode, triodes, maqhubu a matlafalitsoeng, marokho a lokisang, le lisebelisoa tsa motlakase tse fetohang li sebelisoa lipotolohong tse tsamaisang liroboto.Ho phahama ha palo e kholo ea li-harmonics ho ke ke ha ama ka ho teba tsamaiso ea phepelo ea matla feela, empa hape ho kotsi ho senya bophelo le ts'ebetso ea roboto.

Nako ea poso: May-17-2023

.png)

.png)