TTM Group ke k'hamphani e khonang ho etsa lisebelisoa tsa li-automation automation welding.Lihlahisoa tsa rona li sebelisoa haholo lefapheng la tlhahiso ea likoloi, 'me li tšeptjoa ka botebo le ho rorisoa ke bareki.Lihlahisoa tsa rona tsa li-welding tsa likoloi tsa likoloi haholo-holo li kenyelletsa li-welding system tsa robotic, lisebelisoa tsa laser welding, lisebelisoa tse sirelelitsoeng ka khase, joalo-joalo Lihlahisoa tsena kaofela li entsoe le ho hlahisoa ke sehlopha sa rona sa litsebi, se nang le ts'ebetso e phahameng, botsitso le polokeho.

Kaha sebopeho sa likoloi se rarahane ho feta sa lihlahisoa tse tloaelehileng tsa mochini, mokhoa oa ho kopanya le oa ho cheselletsa o thata, 'me bophahamo ba tlhahiso bo boholo, haholoholo tlhahiso ea' mele oa koloi esale e le indasteri e nang le lits'ebetso tsa theknoloji e phahameng haholo.Ntho ea bohlokoa haholo ke liroboto le li-calculator tse kholo tsa li-welding.Mohala oa tlhahiso ea tjheseletsa ea 'mele o entsoe ka lisebelisoa tse tsoetseng pele tsa ho kenya mashala.

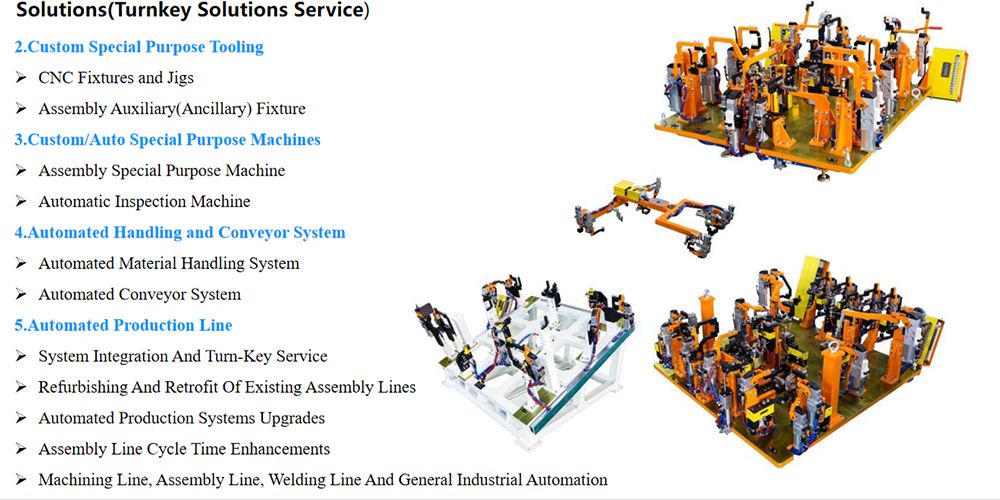

Boholo ba 'mele oa koloi o entsoe ka likarolo tsa tšepe le likarolo tse koahelang, le likarolo tse fapa-fapaneng tse entsoeng esale pele, tse kang litšiea tsa windshield, litšiea tsa mamati, litšepe tse ka holimo tsa mamati, li-fenders tse ka pele le tse ka morao, liphanele tse ka pele le tse ka morao, likoahelo tse ka holimo, joalo-joalo. li bokelloa ka ho tjheseletsa le ho riveting, tseo ho tjheseletsa e leng mohato o bohlokwa moleng wa kopano ya koloi.

Lilemong tsa morao tjena, baetsi ba likoloi tse kholo tsa malapeng ba nkile mela ea ho tjheseletsa 'mele ea liroboto, 'me ba bangata ba bona ba bonts'itse matla a pele a tekheniki lefatšeng.Har'a liroboto tsena, liroboto tsa li-welding li etsa karolo e batlang e le kholo.

Lilemong tsa morao tjena, thekenoloji ea 'mele ea ho tjheseletsa ea laser e nkile sebaka sa theknoloji ea ho tjheseletsa sebaka sa ho hanyetsa, e ka finyellang litlhoko tse phethahetseng tsa ho sebetsana le likarolo tsa koloi.Ho sebelisa theknoloji ena e ncha, bophara bo kopanetsoeng pakeng tsa li-workpiece li ka fokotsoa, e seng feela ho fokotsa tlhokahalo ea lipoleiti E boetse e eketsa ho tiea ha 'mele.Likarolo tsa tjheseletsa tsa laser, ha e le hantle ha ho na deformation likarolong tsa tjheseletsa tsa likarolo, lebelo la ho tjheseletsa le potlakile, 'me ha ho hlokahale hore ho be le phekolo ea mocheso oa post-weld.Laser welding e na le monyetla o motle mabapi le katleho ea mosebetsi, moruo, polokeho, matla le ho hanyetsa kutu.'Me theknoloji ena e ncha e boetse e fetohile mechine le lisebelisoa tse ka sehloohong indastering ea tlhahiso ea indasteri.

Lihlahisoa tsa rona tsa li-automation welding li 'nile tsa sebelisoa haholo likhoebong tse ngata tsa ho etsa likoloi ho thusa bareki ho hlokomela boiketsetso ba tlhahiso, ho ntlafatsa katleho ea tlhahiso le boleng, le ho theha boleng bo boholo ho bareki.Re tla tsoelapele ho khothaletsa boqapi ba theknoloji le lipatlisiso le nts'etsopele ea lihlahisoa, ho fa bareki lihlahisoa le litšebeletso tse betere, le ho thusa nts'etsopele ea indasteri ea likoloi.

Nako ea poso: Apr-28-2023

.png)

.png)