Hemming die le hemming system bakeng sa indasteri ea likoloi

Ntlafatso ea Khampani

- Ka 2011, TTM e thehiloe Shenzhen.

- Ka 2012, Ho fallela DongGuan;Ho theha likamano tsa tšebelisano le Magna International Inc.

- Ka 2013 Ho hlahisa lisebelisoa tse tsoetseng pele ho feta.

- Ka 2016, E hlahisitse lisebelisoa tse kholo tsa CMM le lisebelisoa tsa 5 axis CNC;E sebelisana le merero ea OEM Ford e Felletseng ea Porsche, Lamborghini le Tesla CF.

- Ka 2017, Ho fallela sebakeng sa hona joale sa semela;CNC e ile ea eketseha ho tloha ho 8 ho ea ho 17 lihlopha.Top Talent Automotive Fixtures & Jigs Co.Ltd e thehiloe

- Ka selemo sa 2018, E sebelisana le LEVDEO koloi mme e phethetse mohala oa tlhahiso ea likoloi.4-axis high-speed CNC e ile ea hlahisoa, kakaretso ea Qty ea CNC e fihlile ho 21.

- Ka 2019, Dongguan Hong Xing Tool & Die Manufacturer Co.,Ltd e ile ea thehoa.(Tshebeletso e le 'ngoe) E sebelisana le Tesla Shanghai le Sodecia Jeremane.Ho ahile laboratori e ncha ea R&D bakeng sa boiketsetso.

- Ka 2020, Re sebelisana le OEM ISUZU naheng ea SA; E phethetse Tšebeletso ea RG06 One-Stop Service.

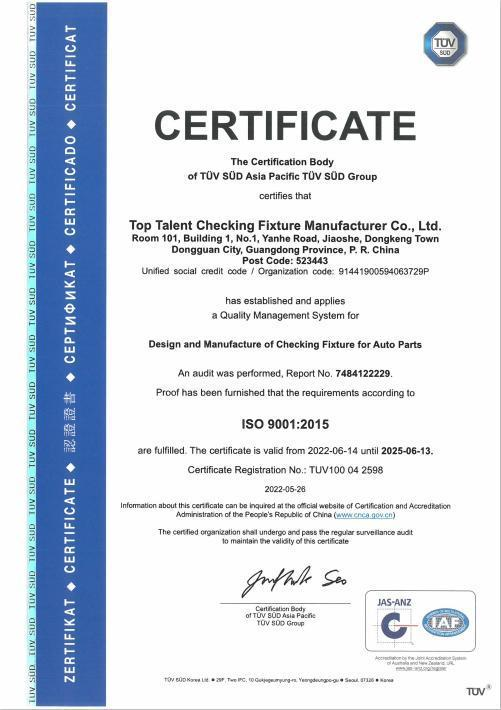

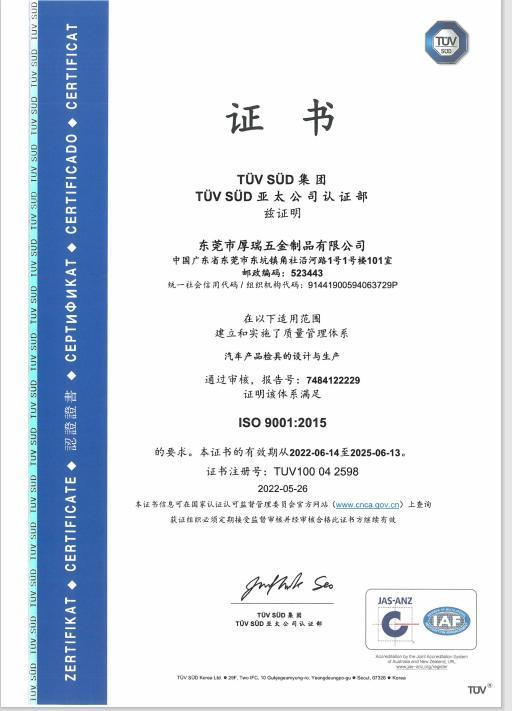

- Ka 2021, Ho hatela pele ka tumelo ea boleng ba ho theha khoebo ea maemo a lefats'e.

- Ka 2022, ofisi ea TTM Group e thehiloe Dongguan City, New CNC 4 axis *5 sets, New Press* lithane tse 630, Hexagon Absolute Arm.

- Ka 2023, TTM e ntse e haha polante e ncha bakeng sa ho lekola khoebo ea ho lokisa thepa le ho cheselletsa;ho eketsa mochine o mong oa khatiso oa 2000T.

Feme ea Fixture ea ho Lekola le Welding (Kakaretso ea sebaka: 9000m²)

Lisebelisoa tsa Setempe le Feme ea Likarolo tsa Mafu le Mechini (Kakaretso ea sebaka: 16000m²)

Tlhaloso ea Lihlahisoa

| Lebitso la Sehlahiswa | Hemming oa shoa |

| Kopo | Li-hoods tsa likoloi, mamati, li-tailgates joalo-joalo. |

| Mofuta | Sistimi ea lefu la tsoekere |

| Pneumatic Component Brand | SMC, FESTO, TUENKERS, CKD, Manual clamp |

| Letšoao la Karolo ea Motlakase | OMRON, Mitsubishi, Siemens, Baluff |

| Sesebediswa(Thibela, Pin ya Sebaka) | 45 # Tšepe, Koporo, Tšepe e se nang Mokelikeli |

| Tsela ea ho Laola | Taolo ea Moea(Pneumatic Control Valve), Taolo ea Motlakase(Solenoid Valve ), Bukana, Ha ho belofo ea solenoid e hlokahalang Fana ka sehokelo. |

| Tsela ea Clamping | Pneumatic, Manual |

| Mokhoa oa puisano | EtherCAT, PROFINET, CC-LINK |

| Lebokose la Relay ea Lipuisano | Tsela ea wiring ea lebokose la motlakase, mofuta oa socket o potlakileng, mofuta oa sehlekehleke sa valve ea Solenoid |

| Tsela ea Piping | Tube e le 'ngoe ea lera, tube e thibelang mollo, Copper / Stainless Steel Tube |

| Kalafo ea Bokaholimo | Ho taka, ho penta+Black Oxidization, Zinc-Coated, Penta ea Phofo |

| Lead time | Libeke tse 2-4 tsa tlhahlobo ea moralo le moralo; |

| Libeke tse 10-12 bakeng sa tlhahiso ka mor'a tumello ea moralo | |

| 7-10 Matsatsi a ho sebetsa bakeng sa ho tsamaisa moea; | |

| Libeke tse 4-5 tsa ho noa leoatleng | |

| Shoa Bophelo | E ipapisitse le bokhoni ba tlhahiso ea moreki |

| Quality Insurance | Tlhahlobo ea CMM |

| Leka ka Mehlala | |

| Onsite Buy-Off | |

| Online video Web Conference Buy-Off | |

| Reka-Off Mathata Ho Rarolla | |

| Sephutheloana | Mabokose a lehong bakeng sa disampole; |

Sefate sa koloi sa hemming ke eng?

Hemming die ea likoloi ke sesebelisoa se ikhethileng se sebelisoang ts'ebetsong ea ho etsa ho bopa le ho boloka mathōko a likarolo tsa tšepe tse etsang 'mele oa koloi.Hemming ke mokhoa o atisang ho sebelisoa indastering ea likoloi ho kopanya likotoana tse peli tsa tšepe ka ho mena ntlha ea lakane e 'ngoe holim'a e' ngoe, ho etsa seam e hloekileng le e matlafatsoang hangata.

Sepheo sa mantlha sa "hemming die" ea koloi ke ho fumana memeno e nepahetseng le e ts'oanang ea tšepe, ho etsa bonnete ba hore mahlakore a kopantsoe ka mokhoa o sireletsehileng.Ts'ebetso ena e bohlokoa bakeng sa ho etsa likarolo tse fapaneng tsa koloi, ho kenyeletsoa mamati, li-hoods, lifenders le likarolo tse ling tsa 'mele.Boleng ba hemming bo ama ka ho toba botšepehi ba sebopeho, ponahalo, le ho tšoarella ha sehlahisoa sa ho qetela sa koloi.

Mona ke lintlha tse ling tsa bohlokoa le mesebetsi ea koloi ea hemming die:

Shaping Edges: Letlapa le etselitsoe ho bopa le ho mena mathōko a tšepe ea lakane ho etsa ponahalo e se nang moroallo le e felileng.Sena ke sa bohlokoa haholo indastering ea likoloi, moo aesthetics le aerodynamics e leng lintlha tsa bohlokoa.

Matlafatso: Hemming ha e fane feela ka chebahalo e hloekileng empa e boetse e tiisa mathōko a kopaneng, e matlafatsang matla le ho tiea ha likarolo tse kopaneng.Sena ke sa bohlokoa bakeng sa ho boloka botsitso ba sebopeho sa koloi.

Ho feto-fetoha ha maemo: Li-hemming dies tsa likoloi li etselitsoe ho amohela mefuta e fapaneng ea botenya ba lishiti le liqapi, tse fanang ka maemo a fapaneng ts'ebetsong ea tlhahiso.Ho ikamahanya le maemo ho etsa bonnete ba hore sesebelisoa se ka sebelisoa bakeng sa mefuta e fapaneng ea mehlala ea likoloi le meralo.

Katleho: Tšebeliso ea hemming e shoa e tsamaisa mokhoa oa ho etsa thepa ka ho iketsetsa ho phutha le ho kopanya likarolo tsa tšepe.Sena se lebisa katlehong e eketsehileng tlhahisong, ho fokotseha ha mosebetsi oa matsoho, le ho ntlafatsa tlhahiso ka kakaretso.

Consistency: Ho fumana liphetho tse tsitsitseng le tsa boleng bo holimo ke monyetla o ka sehloohong oa ho sebelisa hemming dies.Boiketsetso bo netefatsa hore karolo e 'ngoe le e' ngoe e hlahisoa ka nepo, ho fokotsa monyetla oa ho ba le liphoso le ho fapana ha sehlahisoa sa ho qetela.

Innovation: Tsoelo-pele ea theknoloji ea hemming die hangata e kenyelletsa likarolo tse kang litsamaiso tse feto-fetohang tsa taolo, bohlale ba maiketsetso, le meralo ea modular.Litlhahiso tsena li kenya letsoho ho ntlafatseng taolo holim'a ts'ebetso ea hemming le ho lumella ho kopanngoa ha bonolo ho li-setups tsa morao-rao tsa tlhahiso.

Nts'etsopele ea hemming e tsoetseng pele ea shoa, joalo ka PrecisionHem 2024 e boletsoeng karabong e fetileng, e bonts'a matsapa a ntseng a tsoela pele indastering ho ntlafatsa ts'ebetso, botsitso le boleng ka kakaretso ba lits'ebetso tsa tlhahiso ea likoloi.Hemming dies e bapala karolo ea bohlokoa ho fihlelleng maemo a lakatsehang bakeng sa likoloi tsa sejoale-joale, ho fihlela litlhoko tsa ts'ebetso le botle.

Litharollo(Tšebeletso ea Litharollo tsa Turnkey)

Body In White Assembly Systems:

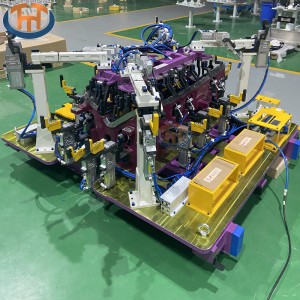

1, Hemming shoa

2, Complete Car Body Welding Line

3, Motho a le Mong a ikemela a le mongWelding Cell

4,Lisebelisoa tsa Welding le Jigs:

CCB TLHOKOMELISOSesebelisoa sa Welding, Floor Pan ASSY Welding Fixture, Wheelhouse ASSY Welding Fixture, AB Ring ASSY AB Welding Fixture, Seat ASSY Welding Fixture, Front Seat Cross Member Welding Fixture, Front End ASSY Welding Fixture, Dash Panel ASSY Welding Fixture, Cowl ASSY Welding Fixture le Rocker ASSY Moetsi oa Welding Fixture, khamphani ea moralo le feme.

Sistimi ea Tsamaiso ea ISO Bakeng sa Hemming Die

Sehlopha sa rona sa Hemming Die

Melemo ea Rōna

Boiphihlelo ba 1.Rich tlhahisong ea boiketsetso le tsamaiso ea khoebo.

2.One Stop Service bakeng sa sesebelisoa sa setempe, ho hlahloba lisebelisoa, lisebelisoa tsa welding le lisele ho finyella nako le ho boloka litšenyehelo, boiketlo ba puisano, ho eketsa phaello ea bareki.

3.Sehlopha sa boenjiniere sa professional ho phethela GD&T lipakeng tsa karolo e le 'ngoe le karolo ea kopano.

4.Turnkey Solution Service-Stamping Tool, Checking Fixture, Welding Fixtures le Lisele tse nang le sehlopha se le seng.

Bokhoni ba 5.Strong le tšehetso ea machaba ea theknoloji le tšebelisano-'moho.

6.Bokhoni bo boholo: Ho hlahloba Fixture, 1500 sets / selemo; Welding Fixture le Lisele, 400-600 lihlopha / selemo;Lisebelisoa tsa Stamping, 200-300 sete / selemo.

Re na le basebetsi ba fetang 352, 80% ea bona e le lienjiniere tse phahameng tsa tekheniki.Karohano ea lisebelisoa: basebetsi ba 130, karohano ea li-Welding: basebetsi ba 60, Ho hlahloba karohano ea thepa: basebetsi ba 162, Re na le sehlopha sa profeshenale sa thekiso le taolo ea merero, merero ea nako e telele ea ts'ebeletso ea mose ho maoatle, ho tloha RFQ ho isa tlhahiso, thomello, kamora thekiso, sehlopha sa rona. e ka sebetsana le mathata ohle bakeng sa bareki ba rona ka Sechaena, Senyesemane le Puo ea Sejeremane.

Merero e Meholo Boiphihlelo ba Lisele tsa Welding le Litokiso tsa Welding

| Morero o Moholo oa Litokiso tsa Welding(2019-2021) | |||||

| Ntho | Tlhaloso | Mofuta | Lebitso la Morero | Bongata(Lihlopha) | Selemo |

| 1 | CCB WF | Arc Welding | VW MEB31 | 60 | 2019-2021 |

| 2 | CCB WF | Arc Welding | VW MEB41 | 10 | 2020 |

| 3 | CCB WF | Arc Welding | VW 316 | 4 | 2020 |

| 4 | CCB WF | Arc Welding | Ford T6 | 8 | 2021 |

| 5 | CCB WF | Arc Welding | ISUZU RG06 | 3 | 2020 |

| 6 | CCB WF | Arc Welding | Bcar, BSUV | 6 | 2020 |

| 7 | CCB WF | Arc Welding | Bcar, BCAR | 7 | 2020 |

| 8 | Mokato Pan WF | Sopt Welding | SK326/0RU_K Karoq RU | 15 | 2019 |

| VW316/5RU_K Tarek RU (19003) | |||||

| 9 | WS Spring Link WF | Arc Welding | WL/WS | 4 | 2019 |

| 10 | Crossmember Brackets WF | Arc Welding | WL/WS | 12 | 2019-2021 |

| 11 | Bumper e ka Pele ea WF | Arc Welding | VW281 | 14 | 2019 |

| 12 | Chassis WF | Arc Welding | Setšoantšo sa RG06 | 18 | 2019 |

| 13 | SL ASY le MBR le EXT ASY | Spot le Arc Welding | Ford P703 | 25 | 2019-2021 |

| 14 | CCB WF le Seleng e sebetsang | Arc Welding | Setšoantšo sa RG06 | 6 | 2020 |

| 15 | Front Seat Cross Member WF | Sopt Welding | Volkswagen AG MEB316(20001) | 4 | 2020 |

| 16 | Floor Pan WF le Grippers | Sopt Welding | AUDI/ PORSCHE PPE 41(19017 Phase 1) | 18 | 2020 |

| 17 | Wheel House WF le Grippers | Arc Welding | Ford BX755(19018) | 6 | 2020 |

| 18 | AB Ring WF le Grippers | Arc Welding | Ford BX755(19018) | 14 | 2020 |

| 19 | Dash Panel WF le Grippers | Sopt Welding | Afrika Boroa Ford T6(17028-1) | 10 | 2020 |

| 20 | Cowl WF le Grippers | Spot Welding | Afrika Boroa Ford T6(17028-3) | 6 | 2020 |

| 21 | Front End WF le Grippers | Spot le Arc Welding | Afrika Boroa Ford T6(17025) | 10 | 2020 |

| 22 | Rocker WF le Grippers | Spot Welding | Afrika Boroa Ford T6(19029) | 8 | 2020 |

| 23 | Floor Pan WF le Grippers | Sopt Welding | AUDI/ PORSCHE PPE 41(19017 Phase 2) | 63 | 2021 |

| 24 | Bumper e ka Morao le Chassis WF | Arc Welding | Ford P703&J73 | 36 | 2020-2021 |

| Morero o Moholo oa Litokiso tsa Welding(2022) | |||||

| Ntho | Tlhaloso | Mofuta | Lebitso la Morero | Bongata(Lihlopha) | Selemo |

| 25 | Matlafatso ea Mohala oa Bohareng WF | Sopt Welding | Vinfast VF36 | 8 | 2022 |

| 26 | Floor Pan WF le Grippers | Sopt Welding | AUDI/ PORSCHE PPE 41(19017 Phase 3&4) | 39 | 2022 |

| 27 | Mokato Pan WF | Sopt Welding le Projection Welding | Ford P703 PHEV | 29 | 2022 |

| 28 | Floor Pan WF le Grippers | Sopt Welding | Porsche E4 Floor Pan(21050) | 16 | 2022 |

| 29 | Mokato Tunnel WF | Ho tšoaea ka laser | VW Floor Tunnel(21008) | 2 | 2022 |

| 30 | Setulo ASSY WF le Tooling | Arc Welding | BYD Seat ASSY | 40 | 2022 |

| 31 | Mokato Pan WF | Spot le Arc Welding | Ford Refurbishment | 24 | 2022 |

| 32 | CCB WF | Arc Welding | VW Cyclone CCB(21037) | 10 | 2022 |

| 33 | CCB WF | Arc Welding | VW MQB37(22022) | 16 | 2022 |

| 34 | A&B-Pillar WF | Spot Welding | Gestamp GS2203 | 8 | 2022 |

| 35 | Roboto Cell Base | NA | Leholiotsoana la VW | 4 | 2022 |

Hemming Dies Manufacturing Center

Re ka haha mefuta eohle ea mefuta e fapaneng ea li-welding ho kenyelletsa le boholo bo boholo kaha re na le Mechini e meholo ea CNC.Ka mefuta e sa tšoaneng ea lisebelisoa tsa mechine tse kang ho sila, ho sila, mechine ea ho itšeha ka terata le mechine ea ho phunya, re ka khona ho laola mokhoa oa ho sebetsa ka katleho le ka nepo.

25 lihlopha tsa CNC le 2 shift e sebetsa

1 Sehlopha sa 3-Axis CNC 3000*2000*1500

1 Sehlopha sa 3-Axis CNC 3000 * 2300 * 900

1 Sehlopha sa 3-Axis CNC 4000 * 2400 * 900

1 Sehlopha sa 3-Axis CNC 4000*2400*1000

1 Sehlopha sa 3-Axis CNC 6000*3000*1200

4 Sehlopha sa 3-Axis CNC 800 * 500 * 530

9 Sehlopha sa 3-Axis CNC 900 * 600 * 600

5 Sehlopha sa 3-Axis CNC 1100 * 800 * 500

1 Sehlopha sa 3-Axis CNC 1300 * 700 * 650

1 Sehlopha sa 3-Axis CNC 2500 * 1100 * 800

5 Axis CNC -Mochine

4 Axis CNC -Mochine

Setsi sa Kopano sa Hemming Die

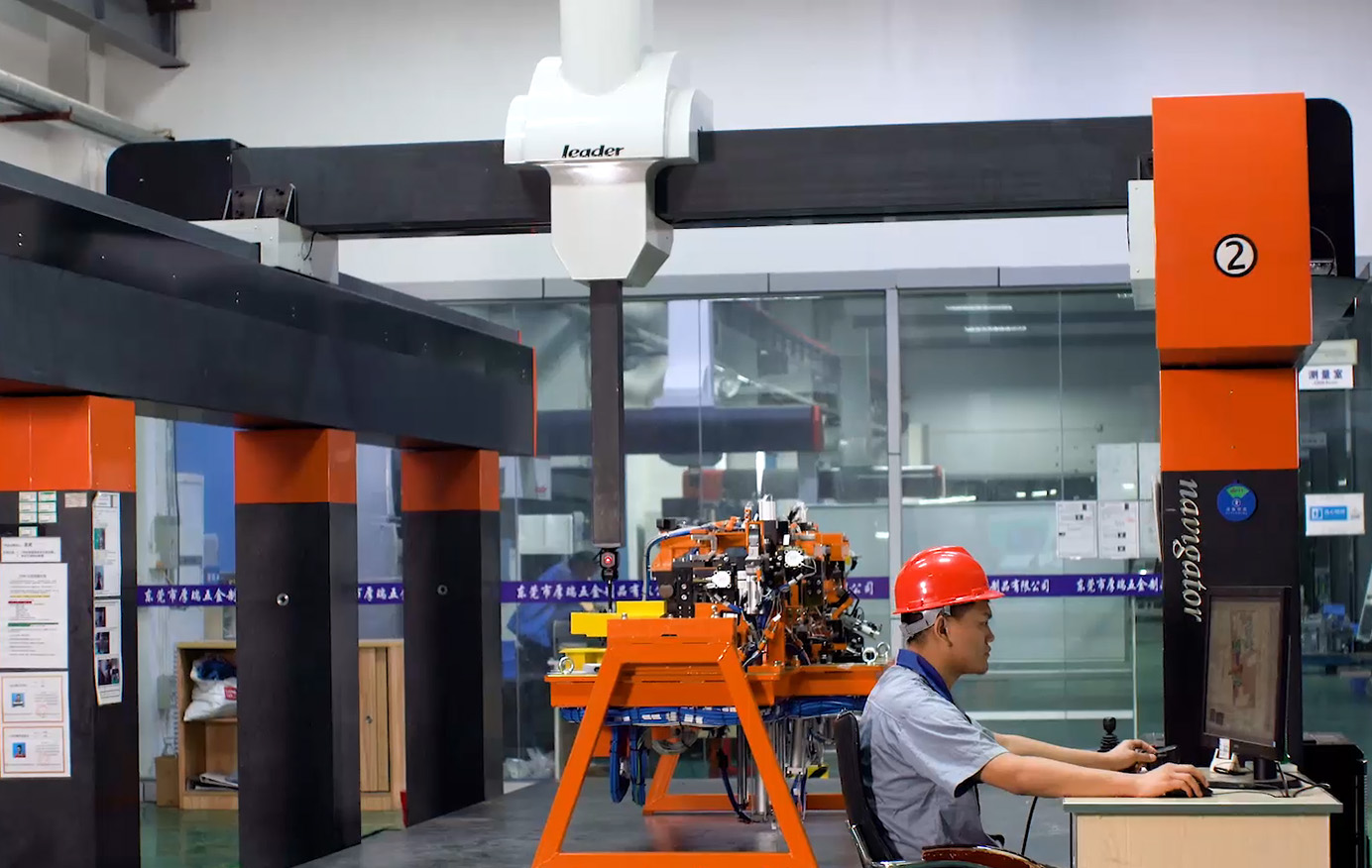

Setsi sa Tekanyo sa CMM Bakeng sa Hemming E Shoa

Obasebetsi ba ur ba koetlisitsoeng hantle ba tla hlokomela nako le nako lenaneong le leng le le leng leo re nang le lona.Re ka etsa tlhokahalo e 'ngoe le e' ngoe ho tsoa ho moreki, ho ba le khotsofalo e kholo ka ho fetisisa ho CMM hape.

3 Lihlopha tsa CMM, 2 Shifts/Letsatsi(10hrs ka shift Mon-Sat)

CMM, 3000*1500*1000 , Moetapele CMM, 1200*600*600 , Leader Blue-light Scanner

CMM, 500*500*400, Hexagon 2D Projector, Hardness Tester

.png)

.png)