moetsi oa litšebeletso tse entsoeng ka setempe sa welding fixture design

Video

Tlhaloso

| Mofuta oa Welding: | ARC Welding |

| Lisebelisoa tsa Welding: | 6 Sets |

| Gripers: | 4Sets |

| Boitsebiso: | Tšepe |

| Libaka tse Rekisetsang kantle: | Canada |

Lintlha tsa Sehlahisoa

Kenyelletso e Feletseng

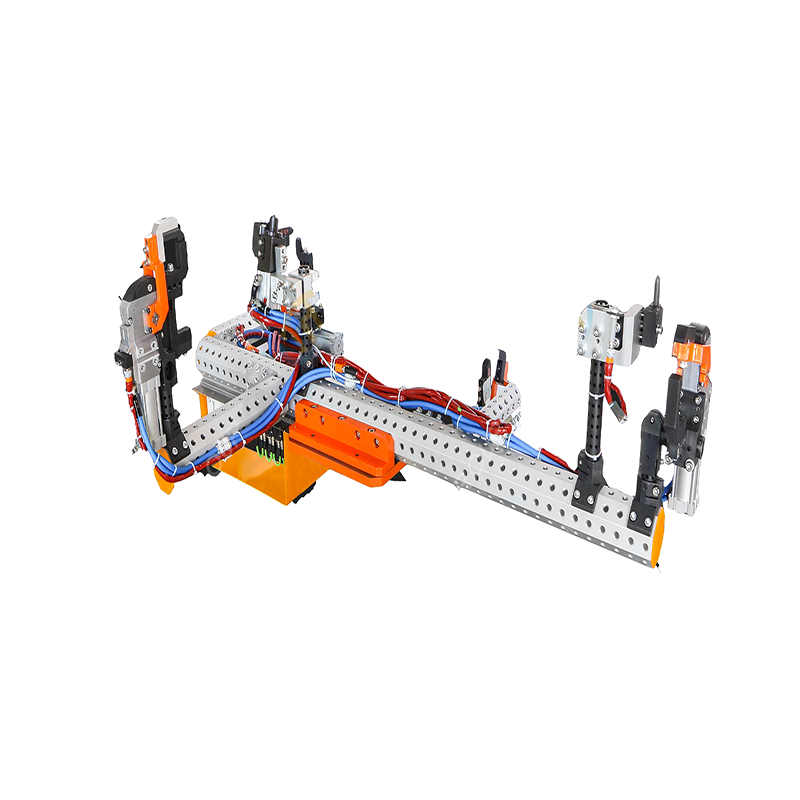

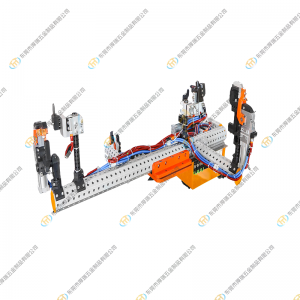

Ena ke sehlopha sa lisebelisoa tsa welding tsa AB Ring, ka li-sets tse 15, tseo re li etselitseng bareki ba rona ba Canada.Mefuta e fapaneng ea li-welding line, batch e nyane le potoloho e khuts'oane ke litšobotsi tsa mantlha tsa indasteri ea sejoale-joale ea tlhahiso ea mochini.Ponahalo ea tšobotsi ena e khothalletsa ho thehoa ha mohopolo oa ho feto-fetoha ha maemo le tsoelo-pele ea theknoloji.Ha potoloho ea ntlafatso ea sehlahisoa e ntse e khutsufala le ho khutsufala, mokhoa oa ho fetoha ka potlako ho tloha ho mehlala ea khale ho ea ho mefuta e mecha le ho khutsufatsa potoloho ea projeke ke tataiso ea lipatlisiso tsa lehakoe ka leng.

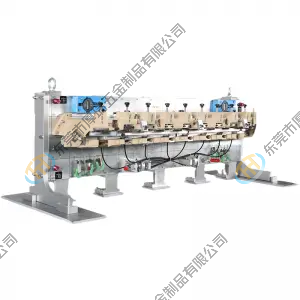

Sesebelisoa sa welding haholo-holo se kenyelletsa poleiti e ka tlase ea fixture, clamp e khethehileng, mochini o thusang, sistimi ea taolo likarolo tse 'maloa.Letlapa le ka tlase ke chassis ea likarolo tsa fixture, sethunya sa othomathike sa welding, lifti le likarolo tse ling tsa fixture.Ke karolo ea motheo ea mochine oa welding, 'me ho nepahala ha eona ho ama ka ho toba ho nepahala ha mokhoa oa ho beha mochine.Circular seam automatic welding machine ke mofuta oa lisebelisoa tsa ho tjheseletsa ka mokhoa o itekanetseng o ka tlatsang mefuta eohle ea li-chelles tse chitja le tsa annular.E ka sebelisoa bakeng sa tšepe ea k'habone, tšepe e tlase ea alloy, tšepe e sa hloekang, aluminium le motsoako oa eona le lisebelisoa tse ling tsa boleng bo holimo, 'me e ka khetha argon arc welding (terata kapa e seng terata), ho qhibiliha ha khase ea electrode, welding ea plasma le matla a mang a tjheseletsa. ho theha ring seam automatic welding system.E ka sebelisoa haholo ho cheselletsa silinda ea hydraulic, foreimi ea tataiso ea koloi, moqomo oa koloi, silinda ea polokelo ea khase, lijana tsa lik'hemik'hale le tsa bongaka, litanka tsa khase tse nang le metsi, lisebelisoa tsa ho loants'a mollo, lirolara le moqomo oa polokelo ea metsi. bakeng sa melapo ea merafo le tlhahiso, joalo-joalo.

Phallo ea Mosebetsi

1. E amohetse taelo ea ho reka-——->2. Moralo-——->3. Ho netefatsa setšoantšo / tharollo-——->4. Lokisetsa thepa-——->5. CNC-——->6. CMM-——->6. Ho bokana-——->7. CMM-> 8. Tlhahlobo-——->9. (tlhahlobo ea karolo ea 3 haeba ho hlokahala)-——->10. (ka hare/moreki setšeng)-——->11. Ho paka(lebokose la lehong)-——->12. Phano

Mamello ea ho Etsa

1. The Flatness of Base Plate 0.05/1000

2. Botenya ba Plate ea Base ± 0.05mm

3. The Location Datum ± 0.02mm

4. Bokaholimo ± 0.1mm

5. The Checking Pins le masoba ±0.05mm

-300x3001.png)

.png)

.png)